Description

Head Gaskets

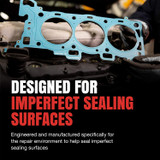

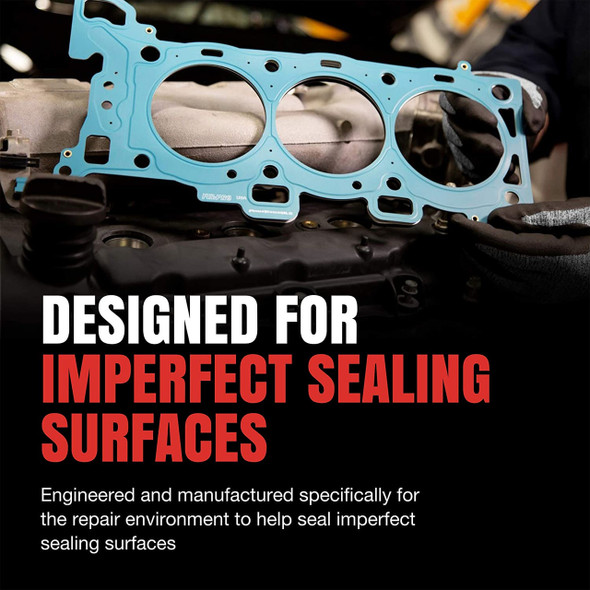

For over 100 years, Fel-Pro Gaskets has been engineering and manufacturing sealing solutions designed for the real-world repair environment to help seal imperfect surfaces. As vehicles age, cylinder heads warp and pit over time resulting in gaskets losing their seal. Worn head gaskets may cause rough engine operation and loss of power, due to degrading compression seal in addition to other critical sealing areas. That’s where the Fel-Pro difference comes in.

Featuring application-specific and propriety technologies such as PermaTorque MLS with LaserWeld, our head gaskets are tested on-vehicle and validated by Fel-Pro to ensure optimal performance.

|

|

|

|

|

|---|---|---|---|

Proprietary CoatingsExclusive coatings help withstand higher engine temperatures and accommodate imperfect sealing surfaces |

Superior SealExclusive sealing innovations and technologies with proprietary materials and unique design features ensure a superior seal for your repair |

Real-World TestedParts are tested on-vehicle and validated by Fel-Pro to ensure optimal performance on the road |

Every Part for the RepairFel-Pro gasket sets include every part needed for the repair unless otherwise noted |

What is a Head Gasket?

One of the most critical gaskets in your engine, the head gasket is designed to seal the cylinders to ensure maximum compression and prevent coolant and engine oil from leaking into the cylinders. The head gasket withstands the stresses of the two surfaces expanding, shrinking, warping and rubbing while sealing in coolant and engine oil running through casting ports.

|

|

|

|

|

|---|---|---|---|

Signs of a Blown/Failing Head GasketBecause the cylinder head gasket seals coolant passages, a blown or failing head gasket will allow coolant to enter the cylinders. Coolant in the cylinders can cause:

|

How to Prepare Engine SurfaceBefore installing a new head gasket, surface conditions of the engine block and cylinder head(s) must be inspected and refinished if they are out of spec. In some cases, damaged castings may need to be replaced. Different gaskets require different surface finishes, so the surface finish must be matched to the type of gasket that is required for the application. Fel-Pro gaskets are designed specifically to accommodate the surface finish requirements for each application. To determine surface finish requirements, consult the OEM repair manual. Checking the cylinder head surface finish and flatness is an important step to take before installing a head gasket. Surface finish can be checked using a surface finish comparator or a profilometer. |

Which Direction to Install a Fel-Pro Head GasketSome gaskets are asymmetric, and the correct orientation can be visually distinguished. Most Fel-Pro head gaskets have directional markings to help install them correctly when gasket orientation is critical to the installation. In some cases, head gaskets won’t have any directional indicators on them. In these cases, it does not matter which direction the gasket is installed. If it were crucial, it would be marked.

|

How to Install Fel-Pro Gaskets – Clean and DryFel-Pro head gaskets are designed so no additional sealers are needed. Fel-Pro's premium materials compensate for surface imperfections and provide the proper amount of torque retention. Always consult the product instructions (where applicable) for sealing requirements prior to installation. |